Rugged,

Reliable Resolver for Position Transducer

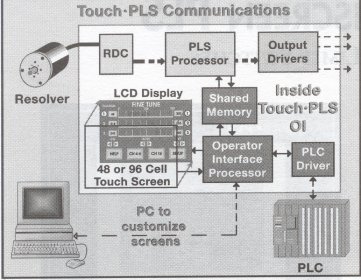

The Touch-PLS

uses a resolver as a position transducer. Unlike incremental

encoders, the resolver, along with its noiseimmune ratiometric

converter, always gives true machine position--even if the machine

moved during a power outage. The resolver, due to its

construction, is immune to temperature and humidity extremes and

mechanical shocks and vibrations.

Short-Circuit-Proof

Resolver

The Touch-PLS uses AVG Automation's standard

short-circuit-proof resolver circuit. Thus, in case of an

accidental short in the resolver wiring, costly damage to the PLS

resolver decoder and the resulting downtime is avoided.

Broken-Wire

Detection

The Touch-PLS features a broken resolver-wire detector to

supervise the resolver input signal. The broken-wire detector will

signal the fault output if the resolver is missing any signals.

FEATURES:

Highest

Processing Speed

Touch-PLS uses AVG Automation's patented DMA technique, which

converts the resolver's analog output signal to a digital form,

then compares all the setpoints, and activates all the outputs in

less than a millisecond. The high-speed ratiometric

resolver-to-digital converter and the microscan time guarantees

perfect machine operation at speeds up to 1,800 RPM.

Multiple

Program Storage

The Touch-PLS can internally store 32 independent programs for

different jobs. With a pre-programmed Touch-PLS for different

product runs, the product change over is as simple as

|

pressing

a button on a touch screen to select the program corresponding to

the job. Remote selection of PLS programs may also be accomplished

by a PLC.

Leading- and Trailing-Edge

Speed Compensation Touch-PLS

features a Speed Compensation (Rate Offset) to compensate for

speed variations. The Rate Offset, individually programmable for

each channel, is used to advance the PLS settings as a function of

the machine speed

Pulse

Programming

Touch-PLS can be fine-tuned while your machine is running. Either

or both of the ON and OFF Setpoints can be incremented or

decremented, or a fixed dwell can be incremented or decremented,

as needed.

Angle

ON/Time OFF

Touch-PLS can be programmed to have its outputs turned ON at an

angle and turned OFF after a programmed time by touching the

screen. For example, Channel 12 can be turned ON at an angle of

100' and stay ON for a period of 2.45 seconds.

Programmable

Functionality: Brake and ModZ

Touch-PLS features a dynamic zeroing or ModZ (Modification Zero)

to modify the zero reference point, independent of the actual

resolver position. After the PLS receives the ModZ input, the

resolver position is reset to zero. Touch-PLS can also perform

Brake Monitoring to satisfy the OSHA requirement. This PLS can be

field-programmed to have Brake Monitoring Functionality (initiated

by entering a Caution and Danger limit). If you do not select

Brake Monitoring, the user must select ModZ or the unit defaults

to normal PLS functionality. (If Brake Monitoring is selected, the

unit cannot function as ModZ.)

Flexible

Group Assignment

Touch-PLS's Flexible Group Assignment can be a powerful and useful

feature. When it is desirable to control several different

machines linked to the same drive shaft, output channels may be

grouped together into one of five independent sections. The base

group is always PLS, while the other four groups (1-4) may be

defined as PLS or ModZ type. Each PLS group has its own group

offset, while each ModZ group has its own ModZ inhibit zone.

Built-in

Motion Detector and Tachometer

Touch-PLS has a built-in tachometer and motion detector. The

motion detector energizes a relay when the RPM is between the

programmed LOW and HIGH alarm values.

|